Safe Launch of Rescue Crafts

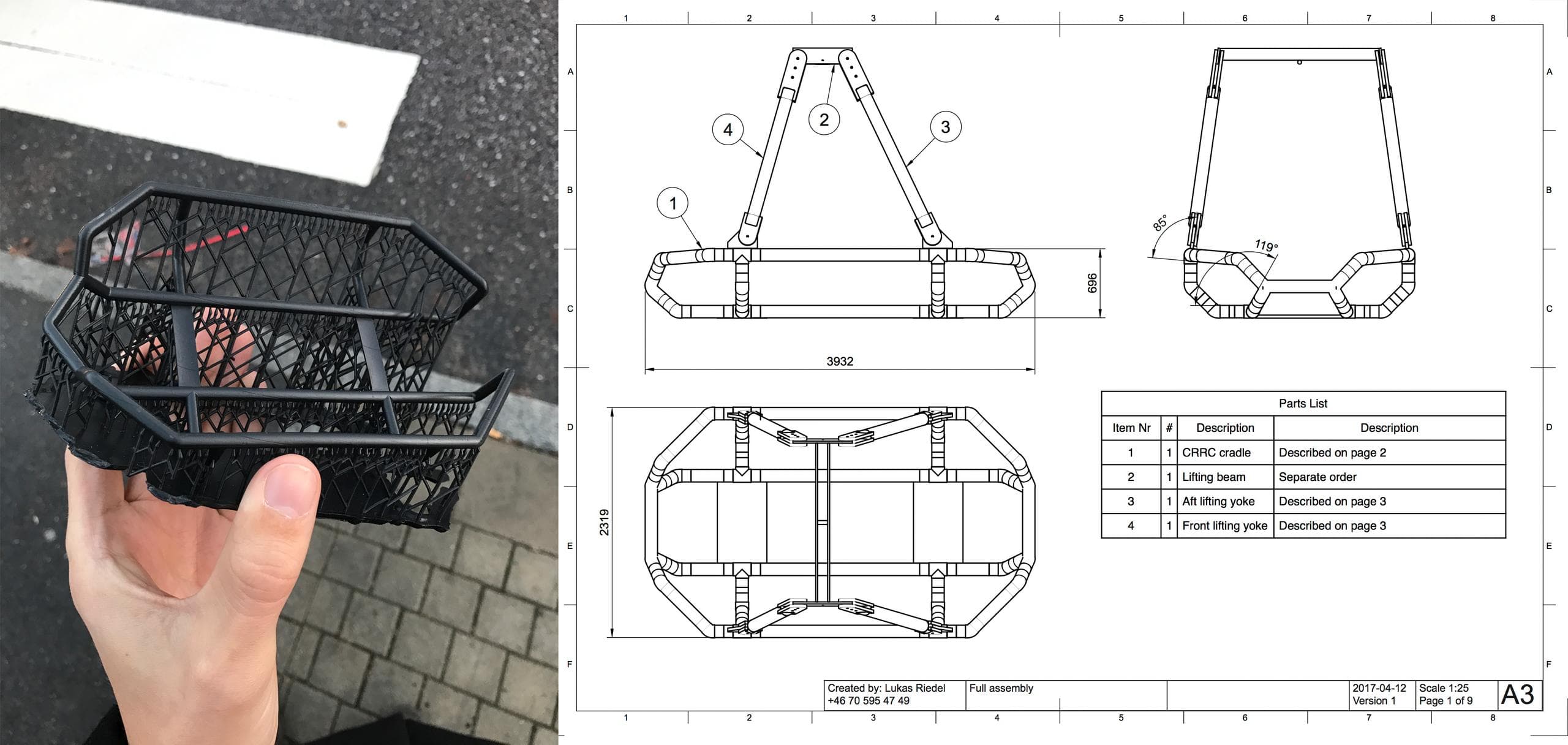

Full of inspiration from doing my Bachelor's thesis, I asked for more employment at the Swedish Sea Rescue Society. They are right now prototyping a new rescue jetski for big passenger ferries which I am designing and constructing the lift cradle for. I also designed a custom fender.

Client

The Swedish Sea Rescue Society

Responsibilities

Industrial Design, Mechanical Engineering

The Base for Design

The Swedish Sea Rescue Society have developed a jetski called the Rescuerunner. This jetski has been successfully used for shallow water rescue and rescue missions where quickness and agility is necessary. It is easily manoeuvred by one person and can handle very rough conditions. For this jetski, a lifting cradle was developed which you can drive into and then be quickly and safely be lifted. My challenge was to learn from the old cradles and design a new one for their newly developed jetski of a considerably bigger size.

Solving the Puzzle

One key feature for the lifting cradle was that it was made out of PE pipes normally used for water piping. This meant for good manufacturability since welding PE pipes is fairly cheap and easy. The pipes are also very durable and do not damage the jetski. The restrictions also made it necessary to use standard pipe bends of 45° and 90° to manage costs wisely. 3D prints together with plant sticks gave good understanding for the final complex assembly.

What About Hydrodynamics?

As this lift cradle is to be used besides big ships under way, it should be possible to drag the cradle in the water safely. This was thoroughly tested at different speeds. The jetski also boarded the cradle during dragging, to ensure easy handling and safety.